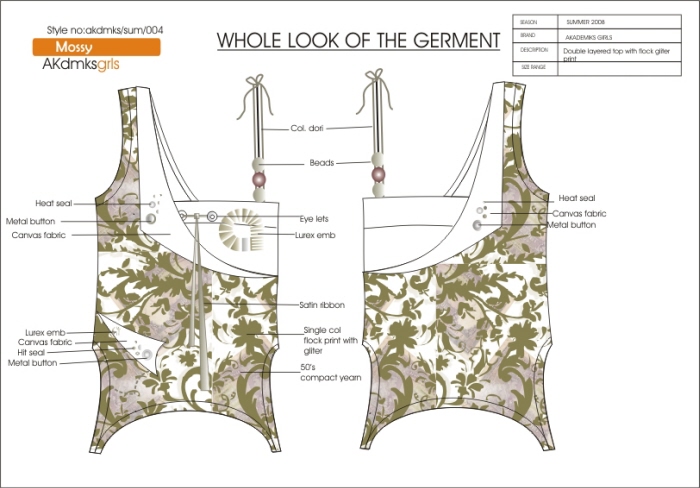

Apparel Tech Pack Design and Production

Finding a reliable clothing manufacturer with low minimum order quantities (MOQs) can be a challenging task for start-up fashion labels. It’s a question that every aspiring brand seeks an answer to. Unfortunately, some manufacturers choose not to address this issue, making it even more difficult for start-ups. However, as a manufacturer and exporter of readymade garments, we strive to be a part of the growing story of start-up apparel brands. Our team offers a comprehensive range of services that are essential for the growth of a brand. From design, tech packs, patterns, sampling, to production, we cover all the crucial aspects that a brand requires. We are well-equipped to handle various types of orders, whether it’s knitted t-shirts, woven garments, denim, or sportswear. Additionally, we have dedicated tech pack designers who can provide support for all collection line-sheets, ensuring a seamless process for our clients.

Urban Purple Fashion Studio is a renowned manufacturer and exporter of ready-made garments, offering a wide range of services to clients in the USA, Europe, and the Middle East. We specialize in apparel design, tech pack design, sampling, and production of knitted, woven garments, and denim jeans. Our state-of-the-art factory in Bangalore, India incorporates advanced technology for top-notch manufacturing processes. Our skilled team of apparel tech pack designers ensures product quality and customization, adhering to industry standards. We actively support clothing brands and private labels, enhancing their global competitiveness through our manufacturing assistance. To prioritize customer satisfaction, we hold necessary registrations and comply with all factory regulations. Since our establishment in February 2008, Urban Purple has been dedicated to delivering exceptional service, quality, and value to our esteemed customers.

Visit our Freelance Fashion Designer Portfolio and get in touch with us with your queries.

PRODUCT DIVERSITIES

Urban Purple with its Associates is capable of producing Knitted , Woven , Denim Jeans , Sweater and Accessories like Leather Belts , Wallets , Bags etc.

Knitted Garments:

At Urban Purple Fashion Studio, we offer a diverse range of products to cater to various apparel needs. Our product range includes innerwear such as men’s and boy’s knitted boxers, ladies and girl’s panties, and men’s and boy’s briefs. We also specialize in men’s and boy’s knitted vests. Additionally, our major product range comprises men’s, ladies, and children’s wear, featuring items such as t-shirts, polo-shirts, sweatshirts, tops, Bermuda sets, short and long skirts, pants, pajama sets, shirts, dresses, caps of different styles, jogging suits, and nightwear. We strive to provide a comprehensive selection of high-quality garments to meet the diverse preferences and requirements of our customers.

Bottom – Pants , Denim Jeans Pants:

We are particularly specialized in Bottoms like Denim & Non-denim pants, trousers, cargo shorts, of both men & women and Kids wear. Capable of Doing any kind of Bottom Specially Denim Jeans and with any kind of Wash Effects and Tearing Effects, Prints , or any kind of style that fits in to the garment.

Woven Tops & Button Down :

Also our Production Line is set for all kinds of Woven Garments like TOPS of all kinds Men’s wear, Women’s wear and Kids wear shirts and button downs, Tops, Blouses in all kind woven fabrics.

Urban Purple : Apparel Production Capacity and Quality Assurance Policy

Urban Purple with its Own Apparel Production Unit and its Associate garment factories comprises of more than 25 garment units across India capable of producing small, medium and large scale garment production of knitted , woven garments and denim jeans. Also have association with India’s Leading Textile Mills, Trims Suppliers, to support with the Fabric Requirements for the Apparel Production.

You are looking for an immediate solution to your ideas ? And getting tech packs takes time ? The best way to convert your ideas to tech packs, purchase and edit tech pack templates. Browse over 100s of high-quality tech pack template and fashion flats, vectors.

For Any Kind of Knitted and Woven Tops Production Please Contact Us Here

Paromita Das – Fashion Designer ( Owner )

Fashion Studio Urban Purple ( Manufacturer & Exporter of Ready made Garments)